FTY-J Series Vacuum Coalescence-separation Turbine Oil Purifier

This equipment use a special polymer materials as filter medium combined with vacuum separating technology and coalescing-separation dehydration system to break emulsification, dewater, degas, remove acid and particles, make the badly turbid turbine oil becomes clean.

Features

1.Vacuum dehydration system combined with Coalescer Type Oil-Water Separator System, rapidly separating and removing various liquid water, free water, trace water, dissolved water, etc.

2.Multi-stage particles filtration system to ensure high filtration precision, pressure gauges installed to display the clogging status of the filter elements.

3.With distinctive removing impurities technique filtering through double FH trapezoidal network and absorbing by high polymer material, this machine can make the ß3 equal or surpass 200 and make the cleanness lower Grade 6 (NAS1638).

4.Duplex-stereo film evaporation technology, equipped with unique and advanced dewatering, degassing components, can rapidly and effectively remove water, gas, particles and volatile matter from the oil.

5.Fastly break the emulsification of the oil.

6.Siemens PLC with large-size touch screen to control the whole operation automatically, displaying vacuum degree, oil temperature, running hours, working status dynamically. 7.Advanced automatic medium cooling system, improving working efficiency and making water content cooled down quickly and removed.

8. Electric control panel with vacuum indicator, pressure indicator, digital temperature controlling system with indicator and automatic shut-down system.

9.Advanced fully automatic temperature controlling system, liquid-level controlling system, pressure protecting system and excellent configuration can ensure operation of the equipment with high performance.

10.Interlock protection system, pressure protection device, interaction of oil inlet ad heating, which avoid influence of incorrect manipulation.

11.Hooks (lifting eyes) installed for convenient lifting.

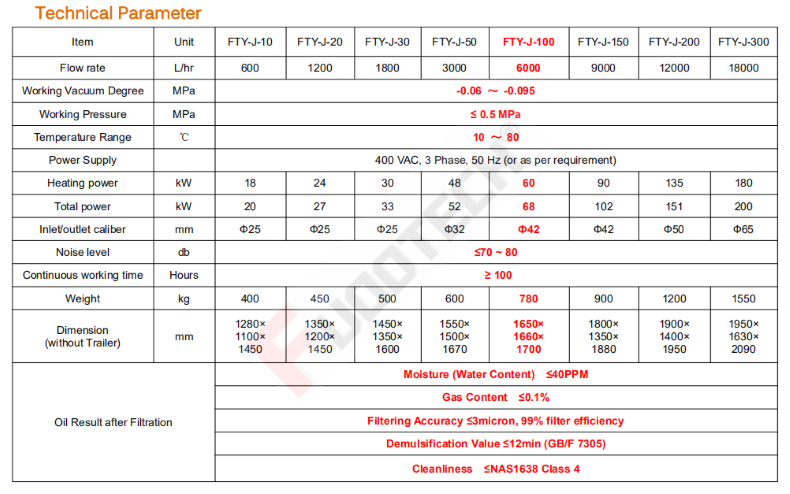

Technical Parameters

Packing and Shipping

Company Profile

QQ: 1227182945

Phone: 19332588324

Tel: WA +86 19332588324

Email: 1227182945

Add: No.5 Hongshi Street, Jiulongpo District, Chongqing, China