Product Overview

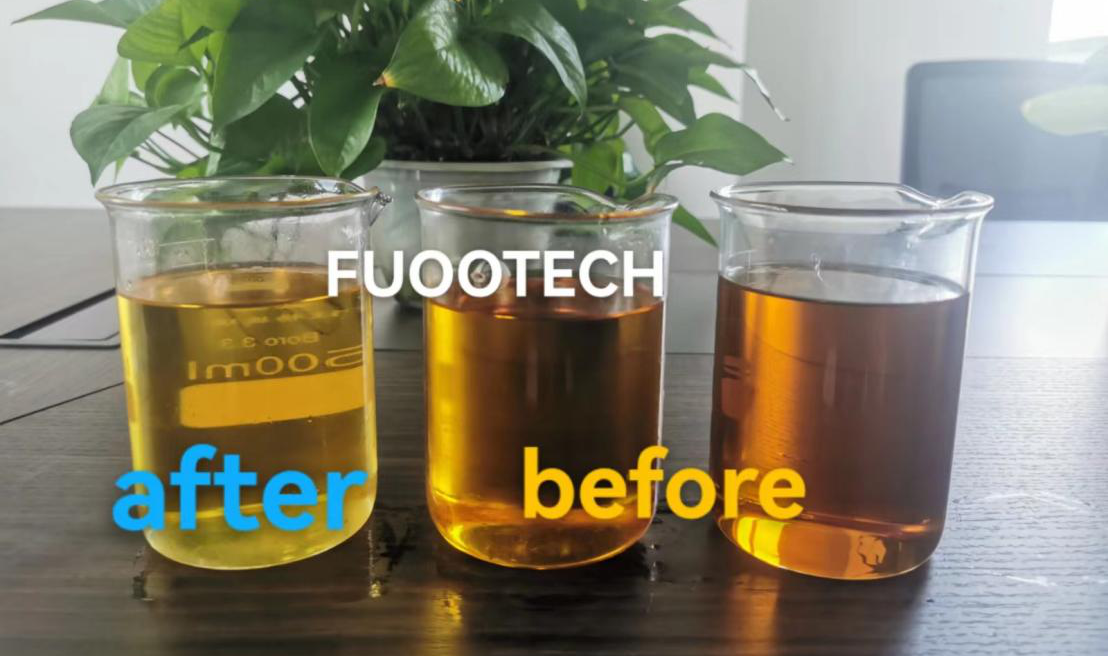

FUOOTECH TYS Series Food Grade Oil Filtration and Decoloration Machine is specially designed to clean the new and used cooking oil, coconut oil, palm oil, dirty vegetable oil, trench oil, swill oil and animal oil, edible rapeseed oil, tea oil, peanut oil, grease etc., It can effectively remove water, particles, alcohol etc. Further more, it can also recover the oil color from black to original yellow. This is combined with our special brand food grade decoloring sands, which is pure natural and has high efficiency. The treated oil is clean, limpidity, and good quality. TYS is a good filtration machine for biodiesel production factory, soap factory, fry food factory, oil restaurant, cooking oil factory, vegetable oil factory, and waste oil collecting store etc.This equipment is widely used to process palm oil made from palm fruit whose color and impurity and moisture cannot meet the use requirements. After processing by TYS oil purification and decoloring equipment, the moisture, gas, impurities and harmful pigments in the oil can be quickly and effectively removed so as to restore the performance indicators of oil quality. The treated oil has a transparent color, low emulsification value, very little water content, and high impurity accuracy. Therefore, this system is widely used in processing and purification in catering industry, food industry, oil chemical industry and other industries.

Features

1. It integrates precision filtration of oil, efficient dehydration, degassing, performance improvement, oil color change, vacuum three-dimensional short-range thin film evaporation technology and electrical control system.

2. Simple to operate, safe and reliable in operation. It can effectively ensure the normal operation of oil-using equipment and avoid accidents.

3. Advanced decolorization processes technology specially for palm oil. Firstly, it ensures that the equipment can operate normally again after the oil is cooled and solidified. Secondly, the equipment uses decolorization products with natural decolorization activity and purification adsorption. The raw ore is a special natural growth. Made of mineral interwoven materials, these unique properties give the processed products a natural decolorizing effect. Not only the quality is good, but also the decolorization efficiency is high. It does not chemically react with grease or general liquids, nor does it change the quality of the oil. It can continuously process a large amount of grease. It is an ideal high-efficiency micro filter.

4. Sophisticated particles removal and filtration system. High-quality filter elements imported from abroad that are resistant to corrosion, high temperature resistance, large dirt holding capacity, and high filtration precision are used to precisely filter the oil to be processed. At the same time, a step-by-step encryption filtration system is used to quickly filter out impurities contained in the oil. and suspended matter, etc.

5. Safe and reliable external oil heating system, optimized pipeline design, the oil flows and heats outside the pipeline during heating, ensuring that there is no "dead oil zone" when the oil is heated, and preventing palm oil from remaining on the inner wall of the pipeline after cooling Inability to circulate leads to excessive local heating and replacement. All tank pipelines and decolorization devices can also be preheated to ensure that the equipment can operate normally again after cooling. At the same time, the heating system is equipped with a constant temperature controller and an oil inlet and outlet interlock protection device to fully realize the automatic operation and shutdown of the heater. When the temperature of the oil flowing through the pipe heater is lower than the set value on the thermostatic controller, the heater automatically starts to heat; otherwise, the heater stops heating.

6. The industry-leading intelligent liquid level automatic control system can comprehensively monitor the liquid level in the vacuum separator, automatically adjust the balance of oil inlet and oil outlet, and truly achieve human-machine separation, making operation more convenient and reliable. Prevent equipment from running out of oil.

7. Adopts special precision oil pump, which runs smoothly in vacuum state, has strong suction energy and low noise, and meets environmental protection requirements.

8. Advanced electrical interlocking safety protection control system. Through the action control of each electrical component, the temperature, pressure, vacuum, liquid level, power outage, over-voltage, under-voltage, overload, etc. of the equipment are comprehensively monitored and protected to ensure the normal operation of the equipment.

9. Equipped with an automatic audible and visual pressure difference alarm device. When the filter element is clogged and the pressure reaches a certain value, an audible and visual alarm signal will be automatically sent out to protect the normal operation of the equipment.

10. Reasonable in structure, easy to install, use and maintain.

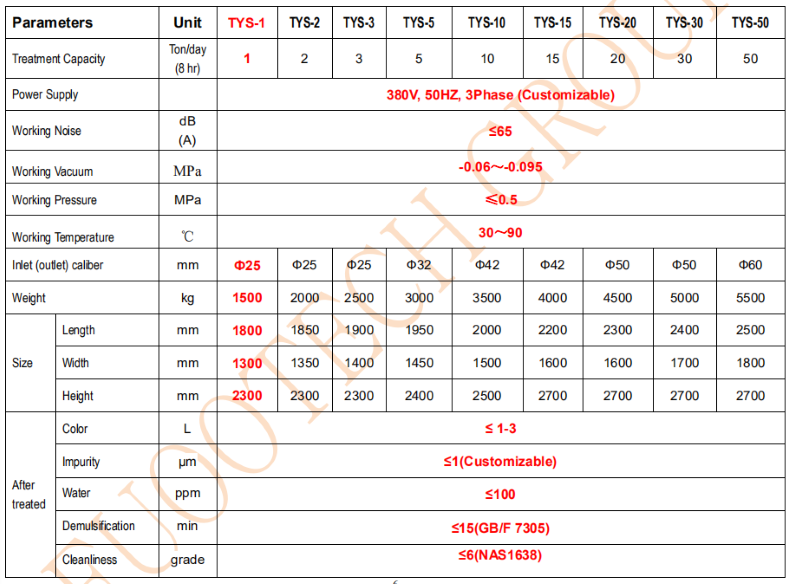

Technical Parameters

Packing and Shipping

Company Profile

QQ: 1227182945

Phone: 19332588324

Tel: WA +86 19332588324

Email: 1227182945

Add: No.5 Hongshi Street, Jiulongpo District, Chongqing, China