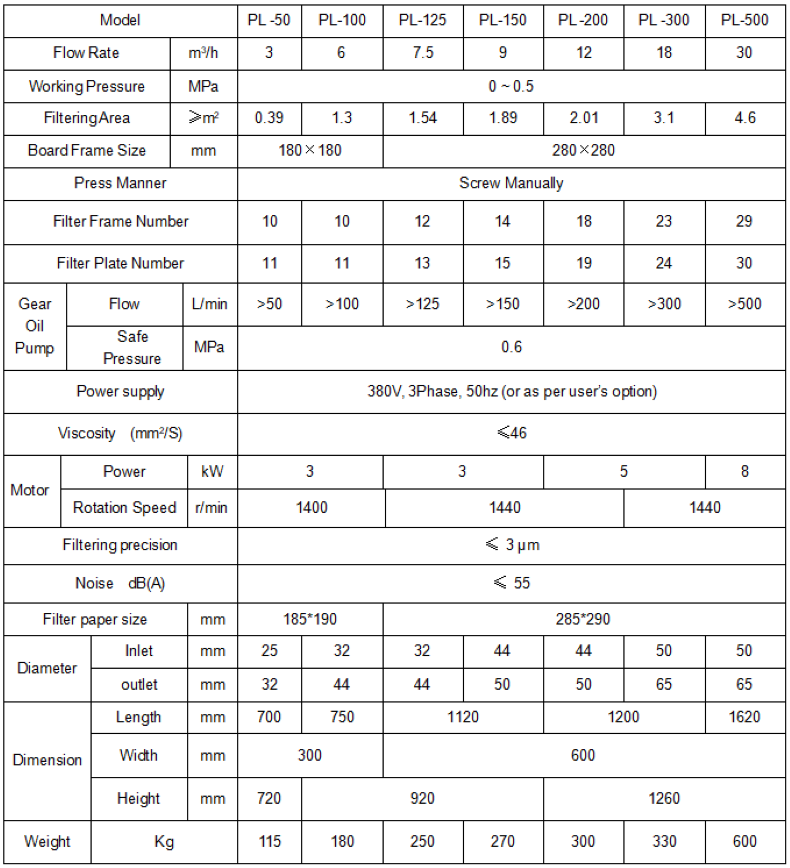

Special boosting type oil pump has strong suction ability and make the machine to be used in more oil types.

Low noise, Quick and convenient to replace filter paper, Simple structure, Easy to use, Lower operation cost.

Due to the limitation of gear structure and installation structure, this machine is not suitable for the cleaning of high viscosity fluids. In regard to the non-lubricating oils like gasoline and kerosene (paraffin), special raw materials and motors need be equipped.

Filtering bed is operated continuously, by the pressure, the dirty oil is sucked into filtering groups which filtering to the side. The groups are made up of a set of alternately sorted filter plates, filter frames, and facility which has Manual Screw Press Device and press plate. There is a lug on the side of filter plate and filter frame to support on the layer board of the machine framework, and There are filtering medias, such as industrial filtering paper or filtering cloth, installed between the filter plate and filter frame that will be fixed to form a single filtering chamber between stationary Thrust plate and movable pressing plate under the pressure of the pressing device. The industrial filtering paper or filtering cloth plays the role of filtration.

There are two liquid holes equipped on the accordant places of filter plate and frame. After pressed, these holes form two integrated Channels. The waste oil is accessed from the trigonal side of the lug, filtered in the filtering chamber, pumped out from fan-shaped side of lug, finally clean oil is obtained.

While filtering, the waste oils are distributed to all the filter frames through the input channel, then enter into filter plates’ liquid holes after pass through industrial papers. Finally, clean oil is integrated in the output channels and pumped to outside.

The Gear Oil Pump and its motor is jointed by flexible rubber gasket. A relief valve is installed at the bottom of oil pump to avoid mechanical troubles because of overhigh pressure. Before delivery in factory, we will set the max pressure value 150%PN. Customer can adjust this value according to the actual situation, but the value can not be over max value.