Fuootech Series FCF Fuel Lube Oil & Turbine Oil Filtration Machine

If the lube oil in your equipment is contaminated with particles and/or water, centrifugal separation is the better way to clean lube oil efficiently. With gravity force, particles and liquids of higher densities than oil are separated in the high-speed separator. The clean lube oil can then be recirculated into the production system, while sludge and water is safely contained to be taken care of separately. Centrifuge oil purifier can work at the same high quality of effectiveness with a high flow capacity while cleaning the oil from both solids and water. FCF centrifugal lube oil purifier is one of the most cost efficient systems on the market, with lower operating costs than other oil cleaning options. With a wide range of centrifugal oil cleaning systems to choose from, ranging from a simple ‘plug and play’ to more sophisticated systems, it is simple to select the module to best suit your needs. Further savings is offered without the need to recurrently purchase filters elements. With cleaner oil, less corrosion and damage are done to the equipment - which can double the lifetime of major machinery.

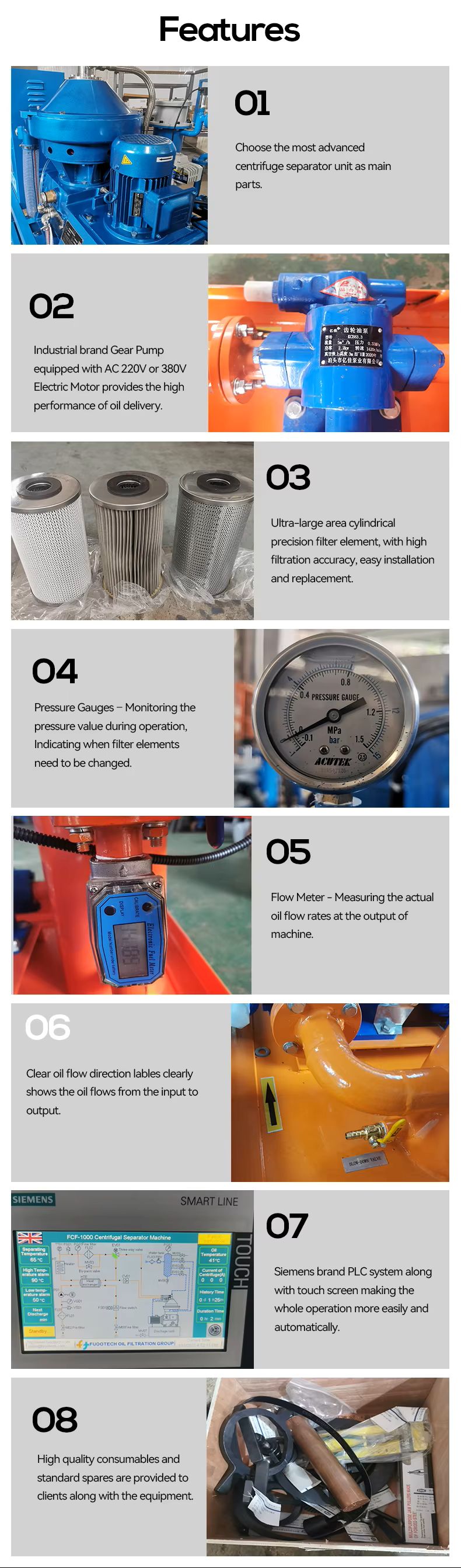

Features

1). High effective Filtration System. Adopting progressive filtering tech, the best precision can be upto 0.5 micron, which can remove more than 99.99% of impurities from the oil.

2). High density heater system, which can speed up water removal by increasing oil temperature that can help water molecule get away from oil molecule more quickly after get heating. But over-heating may damage the oil’s quality, FUOOTECH choose the high density heater system to solve this matter, making the heating load less than 1.5W/cm2, stable temperature controller controls the oil heating temperature automatically, safe and reliable.

3). With famous brands of Electrical components and protection system for over-voltage, over-current, over-load, phases lacking, etc., any problems happen, the whole machine stops automatically. 4). Advanced protection for blockage on oil inlet point where vacuum transmitter is installed, if it’s blocked, machine will stop automatically.

5). Continuous unmanned operation.

6). High separating efficiency.

7). Electric control panel with vacuum indicator, pressure indicator, digtal type temperature controlling system with indicator and automatic shut-down system.

8). Able to be equipped with Heat recovery device as optional.

FCF Oil Centrifuge Machine Brings You

1) Clean your high viscosity oil like heavy diesel, heavy ship oil, lubricant oil;

2) Separate big quantity dirty impurities and particles;

3) Separate high quantity water contamination;

4)Automatic contamination discharge or manual as choices;

5)Protect your machinery and equipment not to be damaged from contaminated oil;

6)Prolong your machinery and equipment lifetime and save maintenance cost;

7)Significantly reduced disposal costs;

8)Maximum operating reliability;

9)Flexible adjustment relating to difficult and changing conditions of the in feed;

10)Nearly oil free discharge (no product loss).

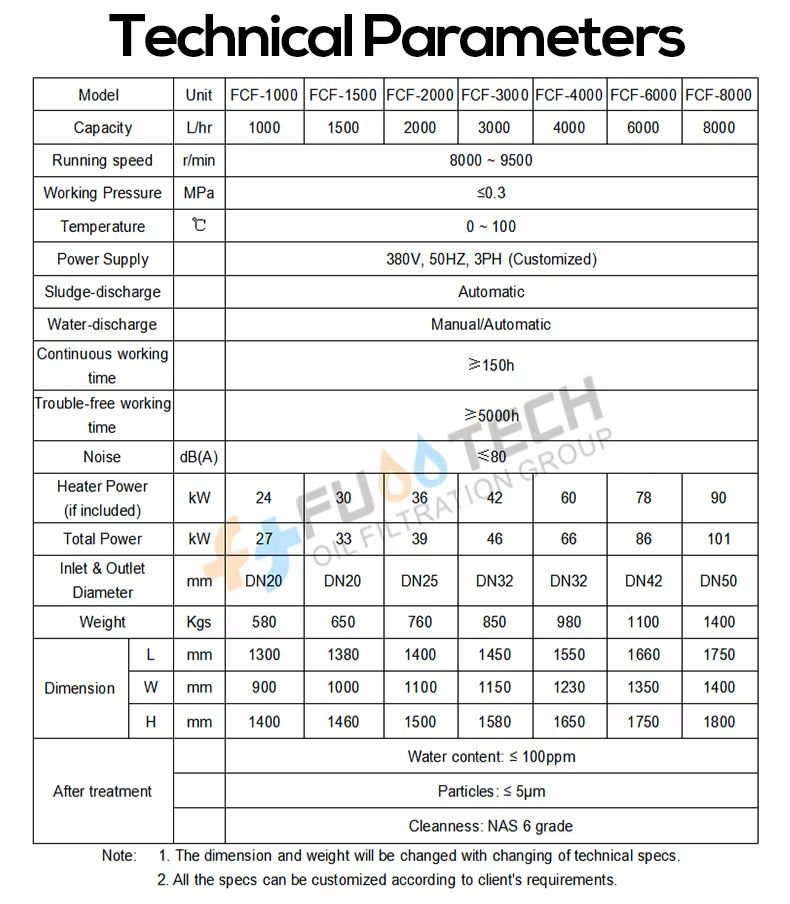

Technical Parameters

Certificates

Packing and Shipping

Company Profile

QQ: 1227182945

Phone: 19332588324

Tel: WA +86 19332588324

Email: 1227182945

Add: No.5 Hongshi Street, Jiulongpo District, Chongqing, China