Product Description

FUOOTECH ZYD-T Series Double-stage Vacuum Transformer Oil Purifier

FUOOTECH® designed, developed and produced ZYD-T Series T-shape Double-stage Vacuum Transformer Oil Purifier according to the preferences of customers from South American such as Mexico, Brazil, Ecuador, El Salvador, Chile, Argentina, etc. and Middle East Countries such as Kuwait, Bangladesh, Pakistan, UAE, Saudi Arabia, etc. starting 2014.

ZYD-T Series T-shape Double-stage Vacuum Transformer Oil Purifier can remove trace water, free water, soluble water, dissolved gas, impurities and tiny particles as well as acetylene, hydrogen, methane and other harmful ingredients effectively and rapidly from used or new transformer oil, so as to improve the flash point, acidity, interfacial tension and dielectric strength value of insulating oil. It suits for purifying all kinds of insulation oils, especially suits for purifying transformer oil from 110KV and above UHV power transmission and distribution projects; also suits for purifying of capacitor oil, mutual inductor oil, switch oil, cable oil.

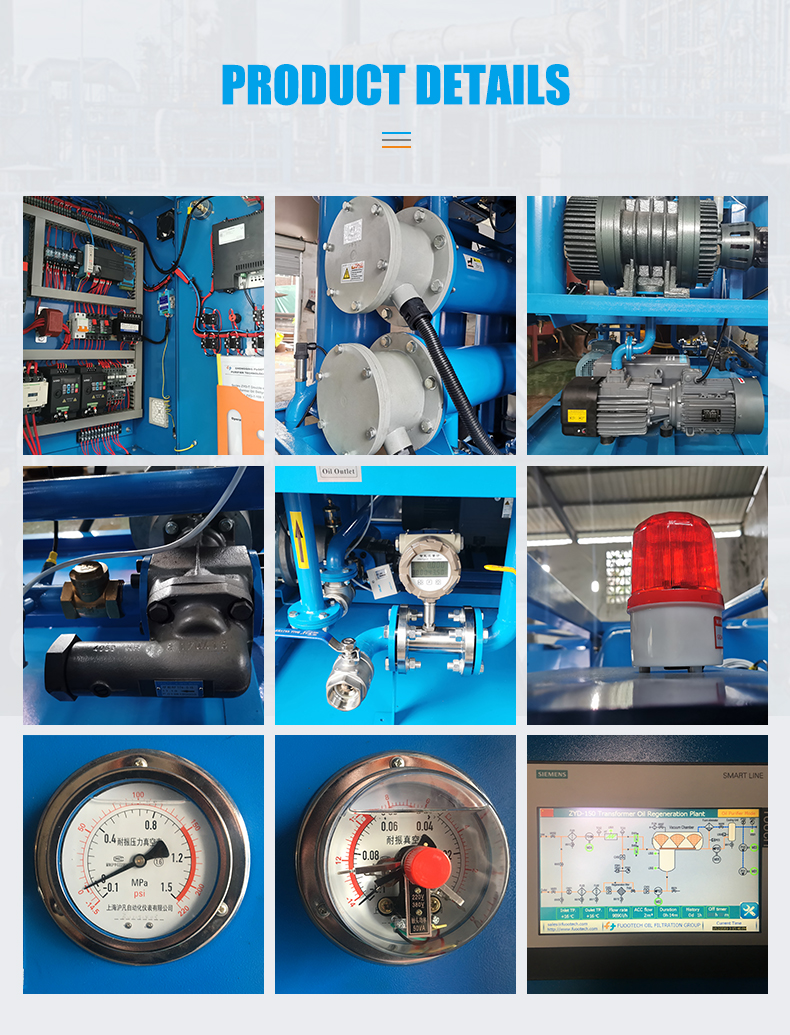

Detailed Photos

Features

1) Special “T” shape double vacuum separation technology, double stages thin film drying degassing technology, double evaporation area and degassing time.

2) Patented degassing tank: anti-foam structure & dual electronic foam monitoring system (key components are from Switzerland), completely eradicating oil entering into vacuum pump.

3) Reliable Control System: Optimized design of control interlock protection device, over-pressure alarm and protection, phase sequence protection, to ensure whole machine working stably for a long time. Automatic pressure alarm system, automatic overload protection system, automatic constant temperature system, automatic foam elimination system, automatic protection of oil blowout prevention and other advanced technologies, ensures the safe and stable operation of unattended operation.

4) Oil atomized particles size is less than 50μm, largely increasing efficiency for water molecules and gas molecules escaping from oil molecules.

5) High density electrical heaters with surface efficiency below 1.5 W/cm2, with indirect heating to prevent local overheating and oil cracking & aging.

6) Install liquid level and temperature protector on the heater system to prevent instantaneous high temperature of heater and blank heating without oil.

7) Vacuum pump cooler preposition, to reduce water or vapor entering into vacuum pump, reduce the frequency to change vacuum pump oil and extend vacuum pump lifetime.

8) High precision filter elements, filter rated up to 1 (0.5 is optional) micron prevents particles from entering back into the transformer.

9) Automatic oil discharge pressure protector, to monitor pressure of oil filters all the time, effectively protecting machine and operators.

10) Adopt the high pressure screw type oil pump, keeping oil delivery stable, low noise, long life.

11) Automatic float ball valve & electronic oil level automatic controlling system, to realize automatic foam elimination, automatic oil level control, unattended operation.

12) Easy to operate, trouble reminder and trouble shooting tips.

Functions

1). Removing Moisture/ dehydration : the final treated oil can achieve less than 3 ~ 5ppm;

2). Degassing: the final treated oil can achieve less than ≤0.05%;

3). Removing Particles: the final treated oil can achieve 1 micron;

4). Vacuum oil filling/transferring;

5). Vacuum drying equipment for transformers;

6). Vacuum purification online work, unattended operation (at certain working condition).

Technical Parameters

Certificates

Packing & Delivery

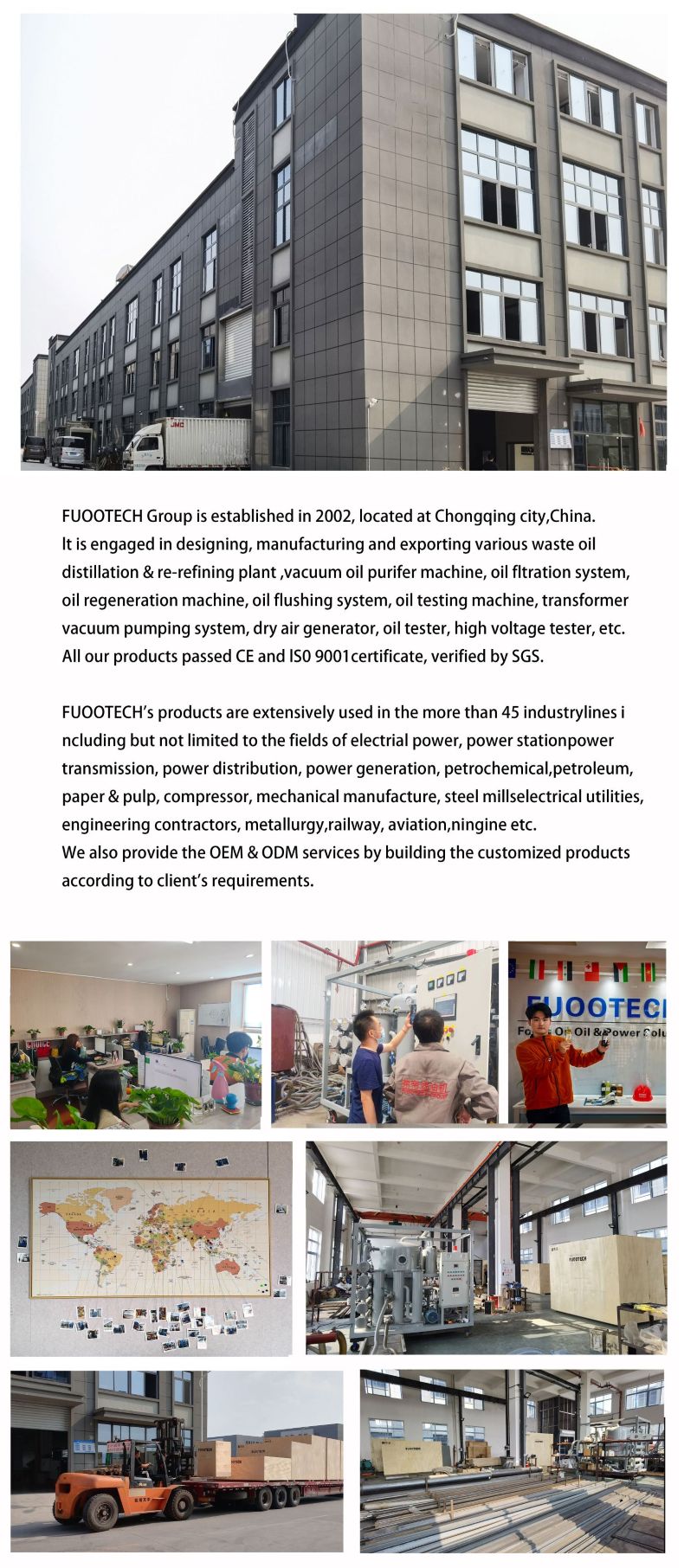

Company Profile

QQ: 1227182945

Phone: 19332588324

Tel: WA +86 19332588324

Email: 1227182945

Add: No.5 Hongshi Street, Jiulongpo District, Chongqing, China